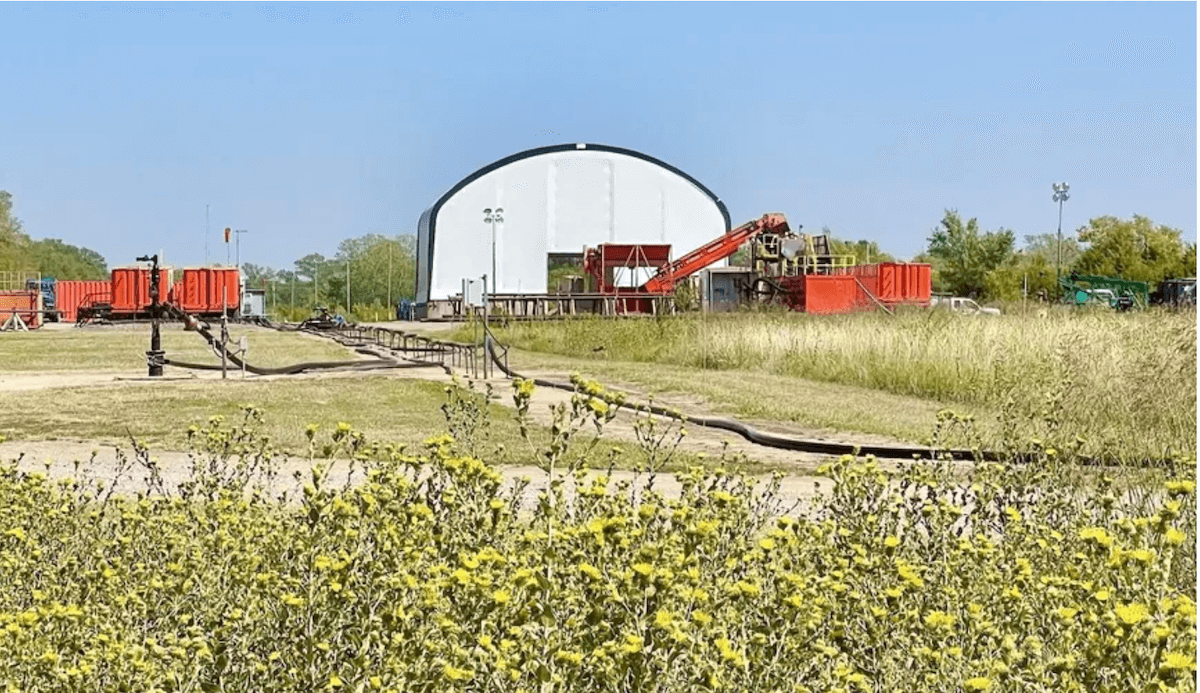

ImpactAlpha, October 28 — Houston-based zero-carbon chemicals producer Solugen has raised over $200 million to fund a new “bioforge” production plant in Minnesota. The facility, which is expected to begin production next year, will be three times larger than Solugen’s flagship plant in Texas.

Solugen’s Houston plant produces more than 11,000 tons of carbon-negative chemicals per year for more than 30 customers in industries such as agriculture, energy, water, infrastructure and personal care products. Solugen counts the U.S. Department of Defense as a customer.

Returning investor Lowercarbon Capital led the new investment round, which pushed Solugen’s valuation to over $2 billion. Participating investors include Fifty Years, Temasek Holdings, climate venture firm Refactor and global asset manager Baillie Gifford. Swedish investor Kinnevik contributed $50 million to the round – and plans to help Solugen break into the European market.

Baillie Gifford and Singapore sovereign wealth fund GIC in September last year led a $357 million raise from the same cohort of investors.

The sustainable chemicals producer says it is on pace to make more than $100 million in revenue this year. Although the firm isn’t profitable yet, Fifty Years’ Seth Bannon told ImpactAlpha, Solugen “is growing into a free cashflow printing machine.” Bannon, who sits on Solugen’s board of directors, added, “Companies like Solugen are utilizing advances in synthetic biology to achieve software-like margins making and selling carbon negative chemicals.”

Solugen launched in 2016 initially to develop a plant-based alternative to hydrogen peroxide, a chemical that’s widely used in everyday products but has a sizable carbon footprint. The company has since expanded its range to chemicals for the food, water, energy, infrastructure and hygiene product sectors.

Solugen’s process: the firm blends feedstocks such as sugars, air, and carbon dioxide with genetically engineered enzymes to create alternatives to conventional chemicals. Wind-powered electricity helps ensure the process has a zero-carbon footprint, which sets it apart from others in the chemicals industry – the largest industrial energy consumer and the third-largest producer of global carbon emissions.